Testing

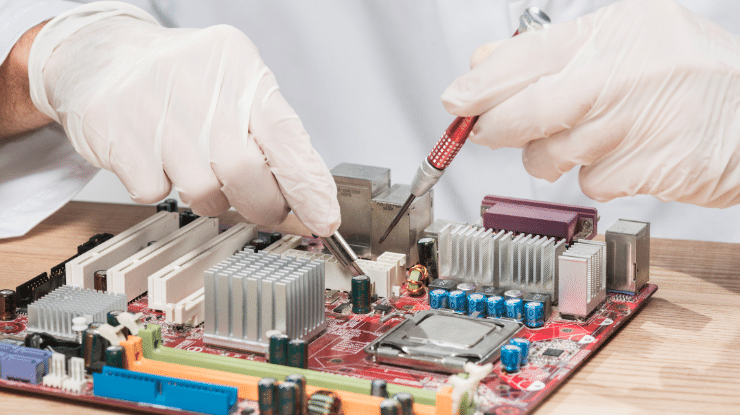

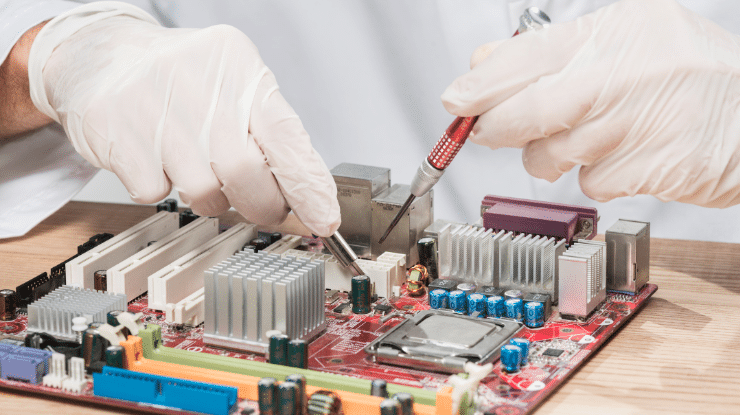

At Quantum Technologies, we prioritize precision and reliability in every printed circuit board (PCB) we manufacture. Our comprehensive testing process ensures that each PCB we produce meets the highest industry standards and functions optimally in its intended application. Testing is a critical part of our quality assurance, ensuring defect-free products before delivery.

We use state-of-the-art equipment and rigorous testing methods to evaluate the performance, durability, and electrical integrity of every PCB. From prototypes to mass production, we implement various testing protocols to identify potential issues early, ensuring long-term reliability and reducing field failures.

Our testing procedures include:

- Automated Optical Inspection (AOI): Detects issues such as misaligned components, solder defects, and missing parts with high precision.

- In-Circuit Testing (ICT): Verifies component values, connectivity, and electrical integrity to ensure the functionality of the circuit.

- Functional Testing: Simulates real-world conditions to ensure the PCB works as expected under operational parameters.

- Flying Probe Testing: A contactless testing method for checking electrical properties and identifying potential short circuits or open circuits.

- Burn-in Testing: Ensures that the PCBs can operate under extended periods of stress and temperature variations, enhancing durability.

At Quantum Technologies, our commitment to quality ensures that each PCB passes through stringent testing, minimizing errors and maximizing performance. With our focus on thorough testing, we deliver products that you can trust to perform consistently in any application.