Through Hole Assembly Process

At Quantum Technologies, our Through Hole Assembly Process is engineered for precision and reliability, ensuring robust connections for PCBs across various applications. Through hole technology (THT) is ideal for components requiring mechanical strength and long-term durability, such as connectors, transformers, and capacitors. Our experienced team follows a meticulous process to guarantee high-quality results for both small and large-scale production.

Key Steps in Our Through Hole Assembly Process:

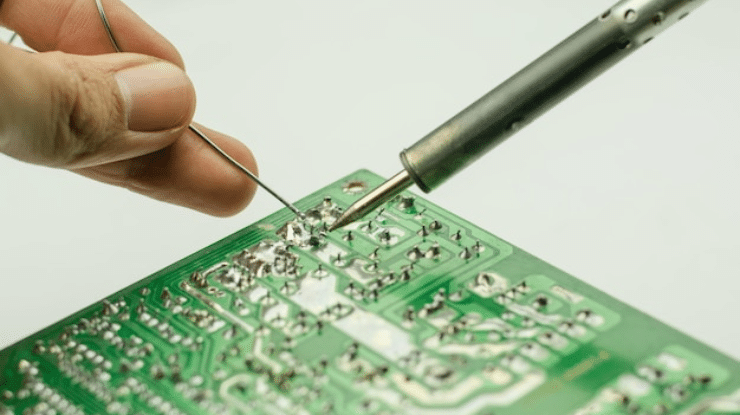

- Component Insertion: Components are manually or automatically inserted into pre-drilled holes on the PCB.

- Soldering: We employ both wave soldering and manual soldering methods to ensure secure, reliable joints. Wave soldering is typically used for large volumes, while manual soldering is reserved for specialized components.

- Inspection and Quality Control: Every board undergoes strict inspection to ensure soldering quality and component placement. We use advanced techniques like Automated Optical Inspection (AOI) and X-ray inspection for complex boards.

- Cleaning: The PCBs are thoroughly cleaned to remove any residual flux or contaminants, ensuring optimum performance.

- Final Testing: Before packaging, each PCB is subjected to electrical testing to verify proper functionality and durability.

At Quantum Technologies, we understand the importance of precision and reliability in through hole assembly. Our process is designed to meet the highest industry standards, ensuring long-lasting, high-performance PCBs for your needs.

Choose Quantum Technologies for your through hole assembly, where quality and precision come first.